Pallet Rack Resources

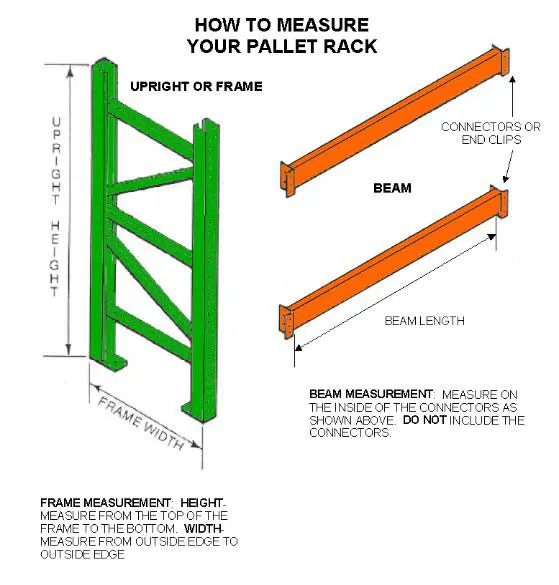

Basic components of pallet rack:

- 1) an upright (also called a frame), and

- 2) a beam. For a more detailed breakdown of rack components, please click here.

A Guide to sizing your rack order

This guide will help determine the upright frames and the beam lengths and capacities needed to meet your load requirements. Questions – don’t worry – just give us a call!

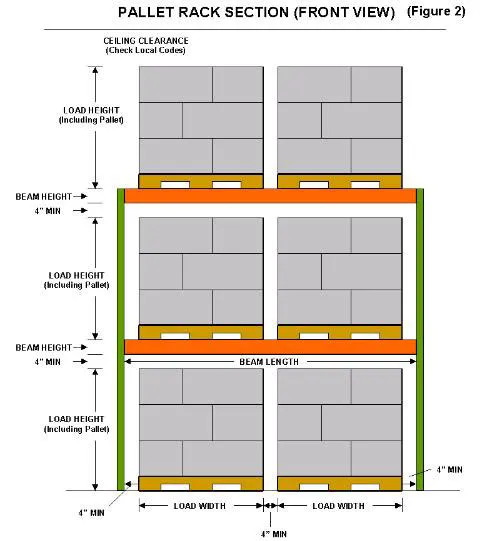

Rack Height: Rack Height is the height of following:

- Height of pallet loads (including the pallet)

- Height of beams

- 4” vertical clearance between top of load and bottom of beam frame/upright height

- If pallet loads are stored on the top of the rack, beam location should be at least 6” less than the fork truck’s lift height.

- Also keep in mind ceiling height and the ceiling clearance required by local codes (See Figure 1 and 2)

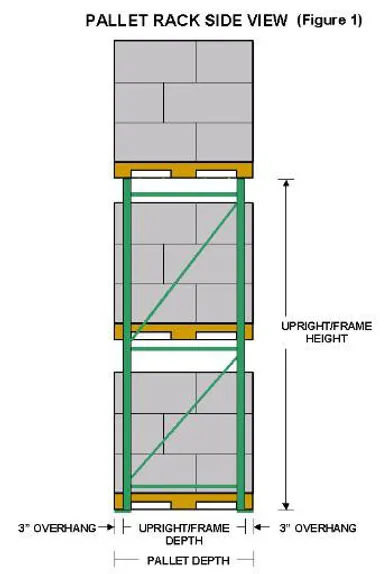

- Rack Depth: Rack depth is the depth of a single upright/frame. It depends on the design and size of pallet used.

- The front and back of the pallet should overhang approximately 3”. Example: a 48” deep pallet requires a 42” deep frame. (3” overhang for both front and back.)

- (See Figure 1)

Beam Length: the distance between a pair of uprights / frames in each rack bay.

- Required beam length is determined by adding the width of pallet loads, plus 4” clearance between pallet loads, plus 4” clearance between loads and each upright/frame.

- (See Figure 2)

Beam Capacity: Beam capacities are based on a pair of beams supporting an evenly distributed load.

- Determine the weight of each pallet load and multiply times the number of loads per shelf. Example: a pallet load weighs 2000lbs and there are two pallets per shelf. A beam capacity in excess of 4000lbs is required.

- (See Figure 2)